Let me tell you something most car manuals won't - removing wiring harness tape can make or break your electrical repair. After 15 years in the auto industry, I've seen too many botched tape removal jobs that led to costly wire damage. Here's the professional approach we use at QKD.

1. Wiring Harness Tape: More Than Just Sticky Stuff

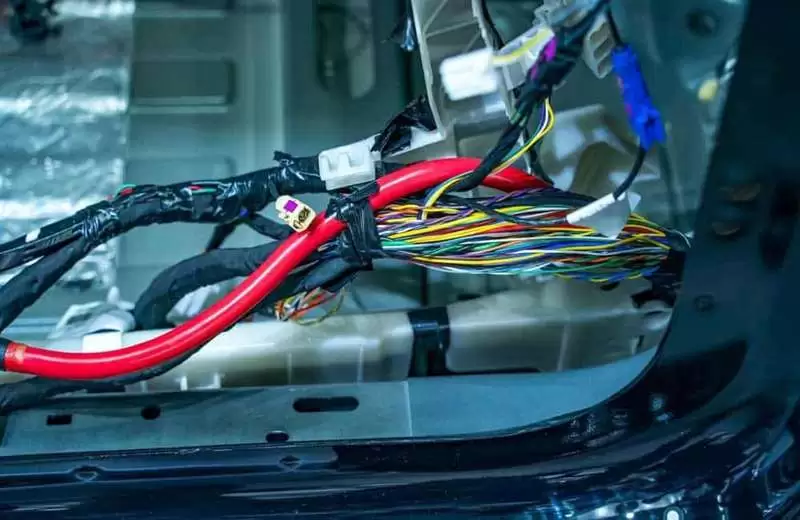

That tape wrapping your wires isn't just there for looks. Quality automotive wiring tape serves three critical functions:

• Protection: Shields against heat (up to 150°C for our PET cloth wire harness tape)

• Organization: Keeps 50+ wires from becoming a spaghetti mess

• Safety: Prevents shorts that could cause electrical fires

The three tapes we see most often:

• Cloth harness tape (common in cabins - soft but leaves fibers)

• Adhesive cloth automotive wiring harness tape (sticks like glue after years)

• PVC harness tape (cheap but melts in engine bays)

2. Why Tape Removal Goes Wrong

Last month, a customer brought us a BMW with $2,000 in wiring damage because they:

1.Used a box cutter blindly

2.Yanked the fabric harness tape sideways

3.Didn't clean adhesive residue before rewrapping

The result? Six severed CAN bus wires and a very expensive lesson.

3. The Pro Removal Kit

In our shop, we keep these essentials:

• Dental picks (perfect for lifting edges)

• Heat gun with temp control (300°F max)

• Kevlar gloves (stops cuts from broken tape)

4. Step-by-Step: How We Do It

Case Study: 2018 F-150 Engine Harness

1.Disconnect - Always start with battery negative

2.Identify - This was wire loom harness tape, which peels differently than standard car wire harness tape

3.Heat - 30 seconds at 250°F loosened the 5-year-old adhesive

4.Peel - Used a rolling motion (like removing a bandage)

5.Clean - Adhesive remover + microfiber wipedown

6.Inspect - Found two nicked wires we repaired before rewrapping

5. Insider Tips

• For adhesive cloth automotive wiring harness tape, twist as you peel to prevent fiber tearing

• In cold weather, warm the tape with your hands first

• Never use metal tools on hybrid battery cables

6. When to Replace (Not Just Remove)

Signs you need new tape:

• Cracking (especially with PVC harness tape)

• Adhesive bleeding through

• More than 5 repair patches

Our go-to replacements:

• Cabin: Cloth harness tape (quieter than alternatives)

• Engine: PET cloth wire harness tape (handles turbo heat)

• Chassis: Wire loom harness tape (abrasion-resistant)

7. Why QKD Tape Stands Out

We engineered our tapes based on real shop frustrations:

• Removes cleanly after years (unlike some fabric harness tape)

• Color-coded for different temperature ratings

• Matches OEM stretchability for proper wrapping tension

8. Final Word

Remember that Toyota recall for wiring chafing? Most failures started with improper tape removal. Whether you're using car wire harness tape for a quick fix or rewrapping an entire harness, doing it right matters.

Keep our temperature-rated automotive wiring tape chart in your toolbox - it's saved my techs countless comebacks.

QKD - Wiring Protection That Works As Hard As You Do